In the world of modern automation and precision control, stepper motors play a pivotal role. These motors are widely used in applications where precise movement and positioning are required, from 3D printers to CNC machines and robotic arms. However, the effectiveness of a stepper motor largely depends on the stepper motor driver, which is responsible for controlling its movement.

A stepper motor driver is a crucial component that translates digital signals into the necessary electrical pulses to drive a stepper motor. Understanding how a stepper motor driver works is essential for anyone involved in automation, robotics, or electronics design. This article will explore the various aspects of stepper motor drivers, from their basic function to their application in advanced systems, ensuring that readers gain a solid understanding of this critical component.

In this article, we will cover four key areas:

What exactly a stepper motor driver is and its importance in various systems.

A detailed explanation of how a stepper motor driver works, breaking down the internal mechanisms and processes.

A more in-depth stepper motor driver explained, where we will look at different types of drivers, their features, and how they differ.

The integration of Modbus stepper drivers, a modern approach that utilizes industrial communication protocols for stepper motor control.

By the end of this article, readers will not only be familiar with stepper motor drivers but will also understand their vital role in ensuring precise motion control in various applications.

What is a Stepper Motor Driver?

A stepper motor driver is an essential component in the operation of stepper motors, which are widely used in applications that require precise positioning, such as robotics, 3D printers, CNC machines, and automation systems. It is a device that takes digital pulses, processes them, and then controls the stepper motor by delivering the correct power signals to its coils. Without a stepper motor driver, a stepper motor cannot function properly, as it relies on these signals to move in discrete steps, offering precision and control.

In its simplest form, a stepper motor is designed to move in fixed increments, or steps, as opposed to a continuous rotation like a traditional DC motor. The stepper motor driver facilitates this movement by energizing the motor’s coils in a specific sequence. The precise control of the stepper motor’s movement is what makes it so useful in applications requiring accurate positioning, such as scanners, printers, and even medical equipment.

At its core, the stepper motor driver works by managing the flow of current to the stepper motor’s windings, determining the number of steps and their direction. In other words, it is the intermediary between the control system (such as a microcontroller or computer) and the stepper motor, translating high-level commands into low-level electrical signals that the motor can understand and respond to.

The stepper motor itself is composed of multiple coils, each of which can be energized in various combinations to produce rotational motion. The stepper motor driver ensures that each of these coils receives the correct amount of power in the right sequence to generate the desired movement. By precisely controlling the timing and sequence of the pulses sent to the motor, the driver ensures that the motor turns in a controlled and predictable manner.

There are several types of stepper motor drivers, and the specific driver chosen depends on the type of stepper motor used, the level of precision needed, and the application requirements. The most common types of stepper motor drivers include unipolar and bipolar drivers. Unipolar drivers are typically used with motors that have a simpler wiring configuration, while bipolar drivers offer more power and precision, making them ideal for high-performance applications.

In essence, the stepper motor driver acts as a translator and a regulator, converting digital input signals into precise movements that allow for accurate control. It is not only important for its ability to control the speed and direction of the motor, but it also plays a role in ensuring the motor runs efficiently and effectively, avoiding issues like overheating or excessive power consumption.

Without a reliable stepper motor driver, a stepper motor could become erratic in its performance, failing to provide the accurate movements required for intricate tasks. For instance, in 3D printing, where every layer of a printed object needs to be placed with precision, the stepper motor driver is what ensures each motor moves by a specific increment with exact control. Similarly, in CNC machines, where the cutting tool needs to be positioned with high accuracy, the driver ensures the motors move as instructed.

In summary, a stepper motor driver is an integral part of stepper motor-based systems, ensuring accurate motion, energy efficiency, and reliability. It transforms the digital pulses into mechanical movement, making it the backbone of precision motion control. Understanding the role and functionality of a stepper motor driver is essential for anyone working with automated systems, robotics, or any application that requires precise motor control.

How Does a Stepper Motor Driver Work?

To fully understand the importance and function of a stepper motor driver, it’s essential to dive into how it works and how it interfaces with a stepper motor to create precise movement. The stepper motor driver is the bridge between the control system (such as a microcontroller or a computer) and the stepper motor, converting digital control signals into the electrical pulses that direct the motor’s movements. Let’s explore this process in more detail.

A stepper motor operates by energizing a series of coils inside the motor. These coils are organized in a particular configuration, typically as part of a stator (the stationary part of the motor), with the rotor (the moving part) positioned in the center. When these coils are energized in a specific sequence, the rotor moves in discrete steps, hence the name “stepper motor.” However, for the motor to move accurately, it requires external control signals to energize the coils in the correct order. This is where the stepper motor driver comes in.

The basic operation of a stepper motor driver involves several key steps:

Receiving Control Signals: The driver receives pulse signals from a controller (like a microcontroller or PLC) that indicates how much movement is required. These signals typically come in the form of digital square waves.

Converting Signals into Power: The driver takes the incoming digital signals and converts them into electrical pulses with the appropriate current and voltage levels needed to drive the stepper motor’s coils. These pulses are usually applied in a particular sequence to make the rotor turn in precise increments.

Coil Energization: The stepper motor driver controls which coils are energized at any given time. By activating different combinations of coils, it ensures that the rotor moves in the desired direction. The timing of the energization determines the step size and speed of the motor.

Step Sequence and Direction: The stepper motor driver ensures that the coils are energized in a specific order to rotate the motor’s rotor in the desired direction. The most common sequence for energizing coils is either a “full-step” mode, where one coil is energized at a time, or a “half-step” mode, which alternates between energizing one or two coils simultaneously, providing finer resolution and smoother motion.

Controlling Speed and Torque: The stepper motor driver also controls the speed at which the motor turns. This is determined by the frequency of the pulses sent to the motor. Faster pulses lead to higher motor speeds, while slower pulses result in lower speeds. Additionally, the driver manages the torque delivered to the motor by adjusting the current sent to the coils, ensuring that the motor doesn’t stall or lose position under load.

The precision of stepper motor movement relies heavily on the accuracy of the pulse signals provided by the stepper motor driver. By controlling the sequence, timing, and intensity of these pulses, the driver ensures that the motor’s rotor moves in precise, fixed increments (or steps). The number of steps in one full rotation depends on the number of coils in the motor and the driver’s step mode, with some motors offering hundreds or even thousands of steps per revolution.

Types of Stepper Motor Driving Methods

The stepper motor driver can be used in different driving modes, each offering distinct advantages depending on the application. These modes primarily vary in how the coils are energized and how fine the motor’s step increments are. The common driving methods include:

Full Step Drive: In this mode, one coil is energized at a time, producing the largest step increments. The motor moves a set number of degrees per step, depending on the number of coils. This mode is relatively simple but less smooth.

Half Step Drive: This mode alternates between energizing one coil and two coils simultaneously. Energizing two coils at once creates smaller steps, resulting in smoother motion and finer control.

Microstepping: Microstepping is the most advanced technique, where the stepper motor driver divides each full step into smaller micro-steps. This method offers the smoothest motion and highest precision, making it ideal for high-resolution applications like 3D printing and robotics.

The Role of Current and Voltage in Stepper Motor Driver Operation

An important aspect of how a stepper motor driver works is its management of current and voltage. Stepper motors typically require higher currents than regular DC motors, and the voltage needs to be carefully controlled to avoid overheating or overloading the motor. Many modern stepper motor drivers come with built-in current limiting features, which regulate the current supplied to the motor’s coils.

In more advanced drivers, the voltage applied to each coil can be dynamically adjusted based on the load or operating conditions. This is known as “current chopping” or “dynamic current control,” where the driver adjusts the pulse width to manage the average current flowing to the motor. By maintaining an optimal current level, the stepper motor driver ensures that the motor operates efficiently, without wasting energy or causing overheating.

In summary, a stepper motor driver works by converting digital control signals into precise electrical pulses that energize the motor’s coils in the correct sequence, enabling it to move in discrete steps. This process involves controlling the timing, sequence, and current delivered to the motor, all of which are critical for achieving accurate movement and precise positioning. The driver’s ability to control the speed, torque, and direction of the stepper motor makes it a crucial component in any system that requires precision motion control. Understanding how a stepper motor driver operates is key to effectively using stepper motors in various automation, robotics, and precision applications.

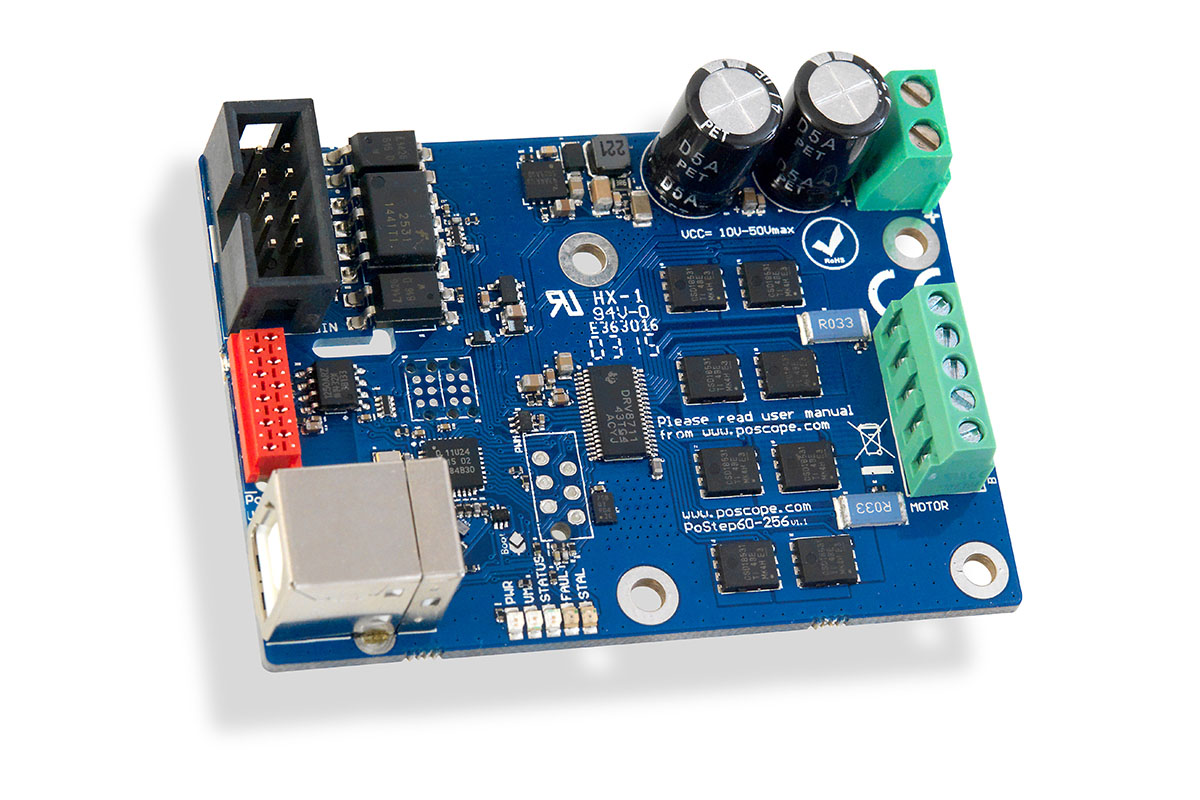

Stepper Motor Driver Explained

A stepper motor driver is not just a simple component; it is a sophisticated device that plays a crucial role in the functioning of stepper motors. Understanding the finer details of how a stepper motor driver operates, the different types available, and how they are applied in real-world systems is essential for anyone looking to use stepper motors effectively. This chapter will provide a deeper explanation of the components and mechanisms that make a stepper motor driver work and explore the various types and their applications.

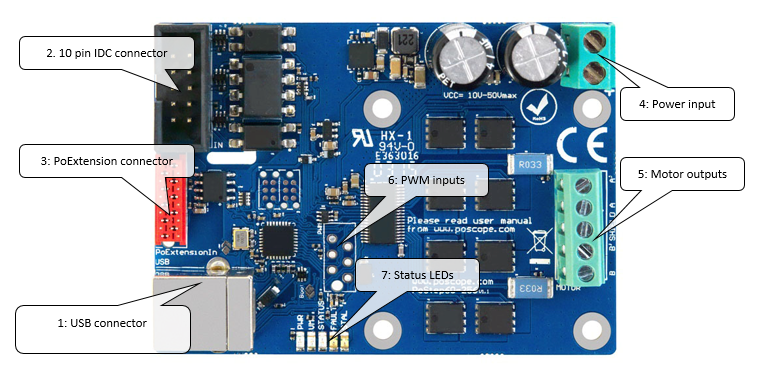

Key Components of a Stepper Motor Driver

At a basic level, a stepper motor driver is composed of several key components that work together to control the motor’s behavior. These include:

Controller Interface: The controller interface is the point where external signals, such as digital pulses or commands from a microcontroller, are input into the system. This interface typically receives control signals that specify movement commands, like the direction of rotation and the number of steps the motor should take. Some drivers support higher-level communication protocols, such as I2C or SPI, allowing for more complex control.

Power Stage: The power stage is responsible for converting the low-power control signals into higher power signals capable of driving the motor’s coils. This component includes power transistors or MOSFETs that switch the current to the coils of the stepper motor. The power stage ensures that the right amount of current and voltage is delivered to the motor, preventing under-driving (which can lead to stalls) or over-driving (which can damage the motor or the driver).

Current Control Circuit: A major role of the stepper motor driver is to regulate the current delivered to the motor’s coils. Stepper motors require precise control over the current to maintain efficient operation and avoid overheating. The current control circuit ensures that the correct current is supplied to each motor coil, which is particularly important when using advanced techniques like microstepping, where smaller current increments are needed for smoother motion.

Step and Direction Control: The stepper motor driver is usually controlled by two main signals: step and direction. The step signal determines how much the motor moves, while the direction signal determines the rotation direction. The step signal is typically a series of pulses, and each pulse moves the motor by one step. The direction signal controls whether the motor turns clockwise or counterclockwise. By managing these two signals, the driver enables precise motion control.

Microstepping Control: Many modern stepper motor drivers have the capability to perform microstepping. Microstepping allows the driver to break down each full step into smaller sub-steps, which results in smoother and more precise motion. For example, a driver that supports half-step or quarter-step microstepping can divide each full step into two or four smaller steps, effectively increasing the resolution of the motor’s movement.

Types of Stepper Motor Drivers

While all stepper motor drivers perform the same basic function of controlling the motor’s coils, there are different types designed for specific applications, each with its own features and benefits. Here are some of the most common types:

Unipolar Stepper Motor Drivers

Unipolar drivers are designed to control unipolar stepper motors, which have coils that are center-tapped. These motors use five or six wires, with each coil having a center tap that provides a reference voltage. In a unipolar driver, current flows through only half of the coil at a time, making the design simpler and the control signals easier to manage.

While unipolar stepper motors are easier to control, they are generally less efficient and offer less torque than bipolar motors. However, unipolar stepper motor drivers are still used in some applications where simplicity and cost are important factors.

Bipolar Stepper Motor Drivers

Bipolar stepper motors do not have a center tap on their coils, meaning that current flows through the entire coil. Bipolar stepper motor drivers are typically more powerful and efficient than unipolar drivers because they can drive both halves of the coil at once, providing greater torque. However, bipolar drivers require more complex control circuitry due to the need to reverse the current direction in the coils, which is essential for proper motor operation.

Bipolar drivers are commonly used in applications that demand higher precision and torque, such as CNC machines and robotic arms.

Chopper or Current-Limiting Stepper Motor Drivers

Chopper drivers, also known as current-limiting drivers, use a technique called “chopping” to regulate the current supplied to the motor’s coils. These drivers periodically interrupt (or “chop”) the current, reducing it to a more manageable level and preventing overheating. This is particularly important when the motor is running at high speeds or when precise current control is necessary to avoid motor damage.

The chopper method is commonly used in high-performance stepper motor drivers and is especially effective in applications where efficiency and heat dissipation are critical, such as in high-end 3D printers and automation systems.

Microstepping Drivers

Microstepping drivers take the concept of precise control a step further by dividing each full step of the motor into smaller fractions. These drivers provide a finer level of resolution, which results in smoother and quieter motion. For instance, a driver capable of microstepping to the quarter-step level will divide each full step into four smaller steps, providing four times more resolution.

Microstepping drivers are commonly used in applications that require highly accurate movements, such as in the medical, printing, and semiconductor industries. They also help reduce mechanical noise and vibrations in the system, making them ideal for applications where noise reduction is important.

Stepper Motor Driver Features and Considerations

When selecting a stepper motor driver, there are several features and considerations to keep in mind to ensure the motor performs optimally:

Voltage and Current Rating: Ensure that the driver’s voltage and current ratings match the specifications of your stepper motor. A mismatch can lead to poor motor performance or even damage the motor or driver.

Control Signals: Make sure the driver is compatible with your control system. Most stepper motor drivers use step and direction control signals, but some may support more advanced protocols, such as SPI or I2C, which may be required in more complex systems.

Heat Dissipation: High-power stepper motor drivers can generate significant heat during operation. Many drivers include heat sinks or other cooling mechanisms to prevent overheating. It’s important to consider the thermal management of the driver, especially in high-load applications.

Step Resolution: Choose a driver that matches the required precision of your application. If microstepping is necessary, make sure the driver supports it and can achieve the desired level of resolution.

A stepper motor driver is a sophisticated device that enables precise control of stepper motors by regulating the current, voltage, and timing of the signals sent to the motor’s coils. It can operate in different modes, such as full-step, half-step, and microstepping, depending on the application requirements. By understanding the components, types, and features of stepper motor drivers, users can select the right driver for their specific needs, ensuring the motor operates efficiently and accurately. Whether it’s for industrial automation, robotics, or precision manufacturing, the stepper motor driver is a critical component in achieving high performance and reliable motion control.

Modbus Stepper Driver: Integrating Communication Protocols for Precise Control

In the world of automation and industrial systems, communication between devices plays a crucial role in ensuring smooth and efficient operations. One of the most widely used protocols for industrial communication is Modbus, a serial communication protocol that facilitates data exchange between various devices. The Modbus stepper driver integrates this communication protocol with stepper motor drivers, enabling advanced control, monitoring, and diagnostics in automated systems.

A Modbus stepper driver is a stepper motor driver that supports the Modbus protocol for communication between the driver and a central controller, such as a programmable logic controller (PLC) or a computer. This integration allows users to manage multiple stepper motors over long distances, reduce wiring complexity, and improve system flexibility. In this chapter, we will explore the features and benefits of Modbus stepper drivers, their working mechanism, and how they contribute to more efficient and scalable automation systems.

What is Modbus and Why is it Used in Stepper Motor Control?

Modbus is a communication protocol developed in 1979 by Modicon (now Schneider Electric) to enable communication between different devices in industrial settings. It is designed to be simple, robust, and easy to implement, making it one of the most popular protocols used in industrial automation, SCADA systems, and process control applications. Modbus allows devices to communicate over serial lines (Modbus RTU) or Ethernet (Modbus TCP), which is especially valuable in environments that require the integration of various devices like sensors, actuators, and controllers.

In a Modbus stepper driver setup, the stepper motor driver communicates with a central control system via Modbus. The central controller can issue commands such as adjusting motor speed, direction, or position, and receive feedback from the driver, such as motor status or error codes. This level of communication ensures that the system operates with high precision, reduces the need for manual intervention, and provides real-time monitoring and diagnostics.

How Does a Modbus Stepper Driver Work?

A Modbus stepper driver operates by exchanging data with a master device (such as a PLC, computer, or industrial controller) via the Modbus protocol. The process can be broken down into several key steps:

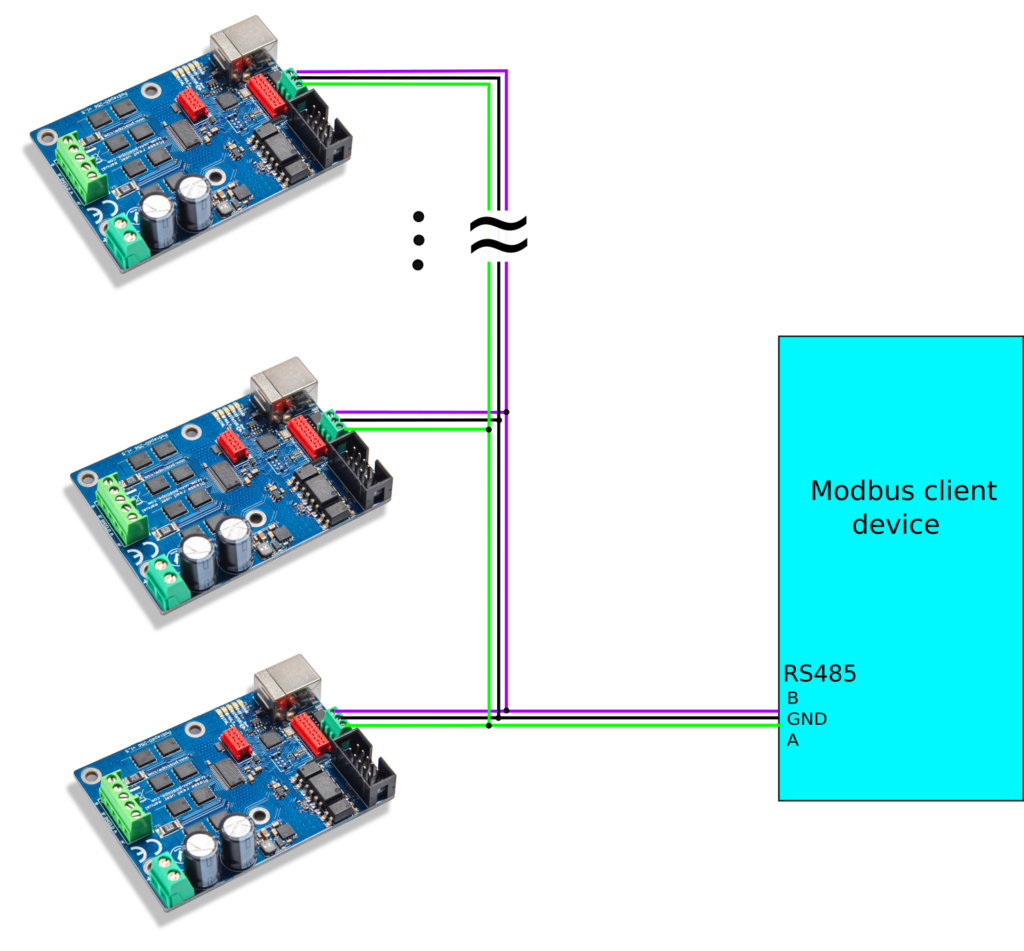

Communication Setup: The Modbus stepper driver is connected to the communication network (typically RS-485 for Modbus RTU or Ethernet for Modbus TCP). The driver is assigned a unique Modbus address, which the master device uses to send and receive data.

Sending Commands: The master device sends Modbus commands (such as read or write commands) to the Modbus stepper driver. These commands could include motor control parameters like step size, direction, speed, or acceleration. The driver processes these commands and adjusts the motor’s operation accordingly.

Motor Control and Monitoring: As the Modbus stepper driver executes the commands, it also sends real-time data back to the master device. This data can include motor position, error codes, current motor status (e.g., running or idle), and diagnostics like overcurrent or overheating. This feedback helps the master device monitor the system’s performance and ensure everything is functioning properly.

Error Handling: The Modbus stepper driver can also communicate any errors or faults it detects. For instance, if the motor experiences a stall or a wiring issue, the driver can report this to the central controller, which can then take corrective actions, such as stopping the motor or adjusting the system parameters to avoid damage.

Multi-Device Integration: A major advantage of using a Modbus stepper driver is the ability to control multiple stepper motors from a single master device. Since Modbus supports addressing, the central controller can communicate with multiple drivers on the same bus, simplifying wiring and reducing the complexity of controlling multiple motors in large systems like robotic arms or CNC machines.

Benefits of Modbus Stepper Drivers

The integration of Modbus with stepper motor control offers several benefits, particularly in industrial and automation applications. Here are some key advantages of using a Modbus stepper driver:

Simplified Wiring: One of the biggest advantages of using a Modbus stepper driver is the reduction in wiring complexity. With Modbus, multiple devices (including stepper motor drivers) can communicate over a single network, drastically reducing the number of wires needed to connect all devices in the system. This makes it easier to scale the system and reduces installation costs.

Remote Control and Monitoring: Modbus stepper drivers enable remote control of stepper motors, which is crucial in large-scale or remote automation setups. Operators can adjust parameters such as motor speed, direction, or position from a central control station. Additionally, real-time monitoring of motor status and performance allows for early detection of faults or performance degradation.

Increased Flexibility: The Modbus protocol supports both serial and Ethernet communication, making it flexible enough to suit a wide variety of industrial environments. Modbus stepper drivers can be integrated into existing Modbus networks with minimal changes, making it easier to add stepper motor control to a pre-existing system.

Scalability: Because Modbus is a master-slave protocol, it allows for easy expansion of the system. New Modbus stepper drivers can be added to the network simply by assigning them a unique address. This scalability is especially important for applications where the number of stepper motors may increase over time, such as in automated manufacturing lines, robotics, or conveyor systems.

Standardized Communication: Modbus is an open and widely supported protocol, meaning that Modbus-compatible stepper motor drivers can be used with a variety of control systems, regardless of the manufacturer. This ensures that system integrators and engineers can easily source components and integrate them into their applications.

Real-Time Diagnostics and Error Handling: Modbus stepper drivers can provide valuable real-time feedback to the control system. For example, the driver can send data about motor temperature, overcurrent conditions, or communication errors, allowing the operator to take proactive measures to prevent system downtime or damage to the motor.

Additional:

Applications of Modbus Stepper Drivers

The ability to integrate Modbus communication with stepper motor control opens up many possibilities for complex automation and industrial systems. Some common applications of Modbus stepper drivers include:

Robotics: In robotic systems, precise control of motors is essential. A Modbus stepper driver allows a central control unit to manage multiple motors, ensuring synchronized movement and accurate positioning in robotic arms, conveyor belts, and automated assembly lines.

CNC Machines: Computer Numerical Control (CNC) machines require precise control of motors for tasks like milling, turning, and engraving. By integrating Modbus stepper drivers with CNC control systems, manufacturers can easily control motor speed, direction, and position from a central interface, improving accuracy and efficiency.

3D Printing: Many 3D printers use stepper motors to control the movement of print heads and build platforms. Modbus stepper drivers in these systems provide enhanced control over the motors, allowing for more precise layer deposition and smoother printing results.

Automated Manufacturing: In automated manufacturing lines, Modbus stepper drivers help control the movement of various machines, conveyors, and other equipment. By using Modbus, operators can remotely monitor and adjust the operations of multiple machines, improving throughput and reducing downtime.

Laboratory Equipment: Precise motor control is essential in laboratory equipment such as microscopes or test instruments. Modbus stepper drivers ensure accurate positioning and fine adjustments, helping researchers achieve highly precise measurements and observations.

Incorporating the Modbus stepper driver into automation systems brings the advantages of remote control, simplified wiring, scalability, and real-time monitoring to stepper motor applications. By using the Modbus protocol, multiple stepper motor drivers can be efficiently managed from a central control point, enabling high levels of precision, flexibility, and diagnostics. The integration of Modbus communication into stepper motor control is particularly beneficial for large, complex systems, and industries requiring synchronized, precise movements across multiple motors. Whether used in robotics, CNC machining, 3D printing, or automated manufacturing, the Modbus stepper driver represents a powerful solution for enhancing automation and motor control.

Conclusion

In conclusion, a stepper motor driver is an essential component in the precise control of stepper motors, enabling systems to achieve highly accurate and repeatable movements. By converting digital control signals into electrical pulses, the driver ensures that the motor operates efficiently and as desired, whether it’s for basic or advanced motion control. Understanding the functionality of a stepper motor driver, including its various types and modes of operation, is key to selecting the right one for a given application, whether in robotics, 3D printing, or industrial automation.

We’ve explored how stepper motor drivers work, with a focus on their core mechanisms such as coil energization, current regulation, and timing, all of which contribute to the motor’s precision. In addition, by discussing the advanced features like microstepping and current chopping, we highlighted how drivers can optimize the motor’s performance, delivering smoother operation and improved efficiency.

As automation and industrial control systems evolve, the integration of communication protocols like Modbus into stepper motor drivers offers significant advantages. The Modbus stepper driver brings the power of industrial communication to motor control, enabling remote operation, real-time diagnostics, and enhanced scalability for systems that need to manage multiple motors. By reducing wiring complexity, allowing centralized control, and providing greater flexibility, Modbus stepper drivers are ideal for modern, large-scale automation systems that require synchronization and precision.

Whether you’re working with a simple automation task or a highly complex system, understanding the fundamentals of stepper motor drivers, along with the advanced features of Modbus integration, can help ensure optimal performance, reliability, and ease of control. In industries that demand precise motion control, the combination of stepper motor drivers and communication protocols like Modbus offers a powerful solution that drives efficiency and innovation, making them indispensable tools in the world of modern automation and robotics.