CNC plasma cutting has revolutionized the metal fabrication industry, offering precision, speed, and versatility in cutting through conductive materials. As technology advances, key components and innovations—such as PlasmaSensOut, CNC plasma cutting, and the CNC Plasma Z-axis & Floating head—play crucial roles in enhancing performance, accuracy, and efficiency. Understanding these elements is essential for operators, engineers, and manufacturers looking to optimize their cutting processes.

This article explores these three critical aspects in depth. First, we will examine PlasmaSensOut, a technology designed to improve plasma cutting precision by monitoring and adjusting torch height in real time. Next, we will answer the fundamental question, “What is CNC plasma cutting?”, breaking down its principles, advantages, and applications. Finally, we will delve into the CNC Plasma Z-axis & Floating head, a system that ensures consistent cut quality by automatically adjusting to material variations.

By the end of this guide, you will have a comprehensive understanding of how these technologies work together to deliver superior cutting performance. Whether you are new to CNC plasma cutting or an experienced professional, this knowledge will help you make informed decisions about equipment, maintenance, and process optimization. Let’s begin by exploring PlasmaSensOut and its role in modern plasma cutting systems.

What is PlasmaSensOut?

PlasmaSensOut is an advanced sensing technology designed to enhance the precision and efficiency of CNC plasma cutting systems. At its core, PlasmaSensOut monitors the plasma arc’s electrical characteristics in real time, allowing the system to make automatic adjustments to torch height, cutting speed, and power output. This ensures optimal cut quality while reducing errors caused by material inconsistencies, warping, or torch wear.

How Does PlasmaSensOut Work?

The technology behind PlasmaSensOut relies on real-time feedback from the plasma arc itself. As the torch moves across the metal, the system continuously measures voltage fluctuations, arc stability, and other electrical signals. If the torch drifts too far from the workpiece or encounters a warped surface, PlasmaSensOut detects these changes and signals the CNC controller to adjust the Z-axis height accordingly. This dynamic response prevents poor cut quality, excessive dross, or torch collisions—common issues in manual or less sophisticated automated systems.

Additionally, PlasmaSensOut can compensate for consumable wear. Over time, electrodes and nozzles degrade, altering the plasma arc’s characteristics. By analyzing these changes, the system can either adjust cutting parameters automatically or alert the operator when parts need replacement, ensuring consistent performance throughout the cutting process.

Why is PlasmaSensOut Important in CNC Plasma Cutting?

Precision is critical in plasma cutting, especially in industries like automotive, aerospace, and heavy fabrication where tight tolerances are required. Without real-time feedback, even minor variations in material height or torch distance can lead to beveled edges, uneven cuts, or excessive slag. PlasmaSensOut eliminates these problems by maintaining the ideal standoff distance between the torch and workpiece, regardless of surface irregularities.

Another key advantage of PlasmaSensOut is its ability to improve productivity. Since the system minimizes manual intervention, operators can run longer, uninterrupted cutting cycles with confidence. This reduces downtime and material waste while increasing throughput—a major benefit for high-volume manufacturing environments.

Applications of PlasmaSensOut

PlasmaSensOut is particularly valuable in industries where precision and repeatability are crucial. For example:

- Metal Art & Decoration – Ensures clean, intricate cuts in decorative metalwork.

- Industrial Fabrication – Maintains consistency when cutting thick or uneven materials.

- Shipbuilding & Construction – Handles large-scale plasma cutting with minimal operator oversight.

By integrating PlasmaSensOut into CNC plasma systems, manufacturers achieve higher-quality cuts, extended consumable life, and greater operational efficiency. As plasma cutting technology continues to evolve, innovations like PlasmaSensOut will play an increasingly vital role in shaping the future of metal fabrication.

Next, we will explore the fundamentals of CNC plasma cutting—how it works, its advantages, and where it excels in modern manufacturing.

What is CNC Plasma Cutting?

CNC plasma cutting is a computer-controlled manufacturing process that uses a high-velocity jet of ionized gas—plasma—to cut through electrically conductive materials such as steel, aluminum, brass, and copper. Unlike traditional mechanical cutting methods, which rely on physical blades or drills, plasma cutting melts and blows away metal with extreme precision, making it a preferred choice for industries requiring speed, accuracy, and versatility.

How Does CNC Plasma Cutting Work?

The process begins when a CNC (Computer Numerical Control) system interprets a digital design file and translates it into precise cutting paths. A plasma torch, mounted on a mechanized gantry, generates an electric arc that passes through a pressurized gas (such as oxygen, nitrogen, or argon). This arc ionizes the gas, transforming it into plasma—a superheated, electrically conductive state of matter reaching temperatures upwards of 30,000°F (16,600°C).

As the plasma jet contacts the metal, it rapidly melts the material while a high-speed gas stream ejects the molten metal, creating a clean, narrow kerf. The CNC system ensures the torch follows the programmed path with exceptional accuracy, allowing for intricate shapes, sharp angles, and smooth curves that would be difficult or impossible with manual methods.

Advantages of CNC Plasma Cutting

One of the primary benefits of CNC plasma cutting is its ability to cut through a wide range of thicknesses—from thin sheets to plates several inches thick—while maintaining high precision. Unlike laser cutting, which struggles with reflective metals like aluminum, plasma systems handle these materials efficiently. Additionally, CNC plasma cutting is significantly faster than oxy-fuel cutting for mid-range thicknesses, making it ideal for production environments where time is critical.

Another advantage is cost-effectiveness. While laser and waterjet systems require higher initial investments and maintenance, CNC plasma cutting offers a strong balance between performance and affordability. The process also produces less heat-affected zone (HAZ) distortion compared to flame cutting, preserving material integrity.

Applications of CNC Plasma Cutting

CNC plasma cutting is widely used across industries due to its adaptability and efficiency. Common applications include:

- Automotive & Aerospace – Fabricating precision parts, brackets, and frames.

- Construction & Structural Steel – Cutting beams, plates, and reinforcements.

- Art & Signage – Creating detailed metal artwork and lettering.

- Industrial Machinery – Producing custom components with tight tolerances.

The Future of CNC Plasma Cutting

With advancements in automation, IoT integration, and real-time monitoring (such as PlasmaSensOut), CNC plasma cutting continues to evolve. Modern systems now feature improved energy efficiency, better consumable life, and enhanced software for optimized cutting paths. As industries demand faster, smarter, and more sustainable manufacturing, CNC plasma cutting remains a cornerstone technology in metal fabrication.

CNC Plasma Z-Axis & Floating Head: How Do They Improve Cutting Precision?

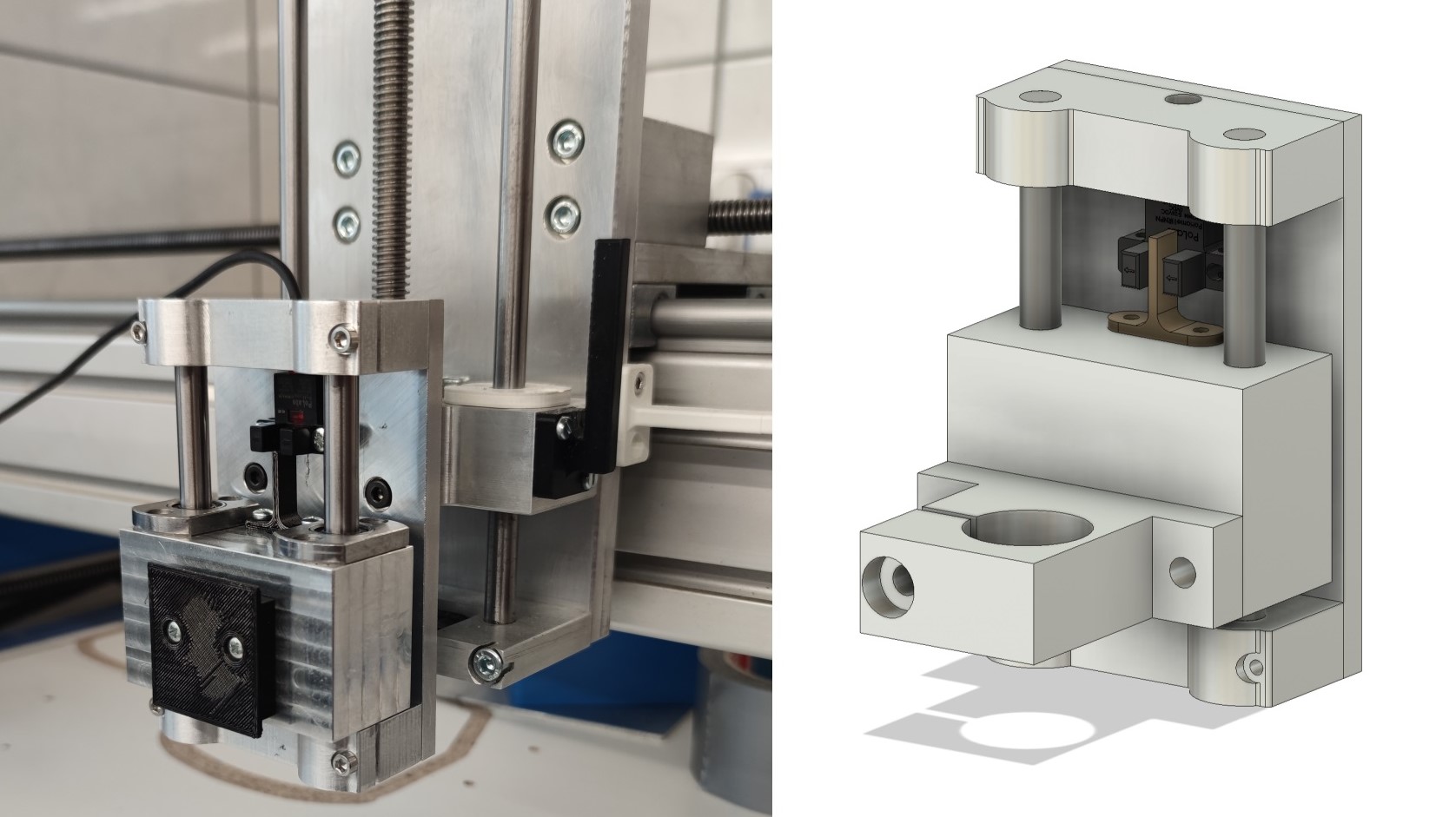

In CNC plasma cutting systems, maintaining the optimal distance between the torch and workpiece is critical for achieving clean, consistent cuts. This is where the CNC Plasma Z-axis & Floating head system plays a vital role. By automatically adjusting the torch height in real time, this technology compensates for material warping, uneven surfaces, and thickness variations—ensuring precision throughout the cutting process.

How the Z-Axis and Floating Head Work Together

The CNC Plasma Z-axis is the vertical movement mechanism that raises and lowers the plasma torch. Meanwhile, the Floating head (or “touch-off” mechanism) is a spring-loaded or pneumatic device that allows the torch to physically sense the material surface before cutting begins. Here’s how they function in unison:

Initial Touch-Off – Before cutting, the floating head gently contacts the workpiece, establishing a reference point for the Z-axis. This ensures the torch starts at the correct height, regardless of material placement.

Dynamic Height Control – During cutting, the Z-axis continuously adjusts based on real-time feedback from arc voltage or sensors like PlasmaSensOut, maintaining the ideal standoff distance.

Collision Prevention – If the torch encounters an unexpected obstruction (such as a warped plate), the floating head absorbs impact, preventing damage to the torch or machine.

Why These Components Are Essential

Without a properly calibrated CNC Plasma Z-axis & Floating head, even the most advanced plasma cutter would struggle with consistency. Variations in material flatness—common in large steel plates or recycled metal—would lead to poor cut quality, excessive dross, or torch crashes. By dynamically adjusting height, these systems:

- Improve Cut Quality – Maintaining the correct standoff distance ensures a stable arc, reducing beveled edges and slag.

- Extend Consumable Life – Preventing improper torch-to-workpiece distance minimizes wear on nozzles and electrodes.

- Enable Faster Piercing – The floating head allows for controlled “pierce height” adjustments, reducing splatter and prolonging consumables.

Applications in Industrial Cutting

Industries that rely on high-speed, high-precision plasma cutting benefit greatly from CNC Plasma Z-axis & Floating head technology. For example:

- Heavy Equipment Manufacturing – Handles thick, uneven plates with minimal operator intervention.

- Shipbuilding – Compensates for warped steel sheets common in large structural components.

- Metal Art & Custom Fabrication – Ensures precision in intricate designs, even on imperfect materials.

Future Developments in Z-Axis Technology

As CNC plasma systems become smarter, advancements in CNC Plasma Z-axis & Floating head designs are integrating more sensors, AI-driven adjustments, and predictive maintenance features. Some modern systems now use servo-driven Z-axis motors for faster response times, while others incorporate wireless feedback for seamless communication with CNC controllers.

By combining these innovations with technologies like PlasmaSensOut, manufacturers are achieving unprecedented levels of automation and precision in plasma cutting.

From Basics to Advanced: A Guide to Stepper Motor Drivers

Mastering CNC Control: A Comprehensive Guide to Mach4 CNC Controller, PoKeys57CNC Pinout, Mach3 Limit Switches, and CNC Mach3 Tutorials

The Synergy of Precision in Modern Plasma Cutting

CNC plasma cutting has evolved from a basic thermal cutting method into a highly sophisticated manufacturing process, driven by innovations like PlasmaSensOut, CNC plasma cutting automation, and the CNC Plasma Z-axis & Floating head. Together, these technologies address the key challenges in metal fabrication—precision, efficiency, and adaptability—ensuring that industries can meet increasingly demanding production standards.

PlasmaSensOut exemplifies how real-time monitoring elevates plasma cutting by dynamically adjusting torch height and power based on arc conditions. This not only improves cut quality but also reduces material waste and extends consumable life. Meanwhile, the fundamental principles of CNC plasma cutting—speed, versatility, and computer-controlled accuracy—make it indispensable for industries ranging from automotive to artistic metalwork. Finally, the CNC Plasma Z-axis & Floating head system ensures that even imperfect materials are cut with consistency, preventing errors and machine damage while optimizing performance.

The future of plasma cutting lies in further integration of these technologies. Smart systems with AI-driven adjustments, IoT connectivity for predictive maintenance, and enhanced motion control will continue pushing the boundaries of what’s possible. As manufacturers seek faster turnaround times and tighter tolerances, advancements in PlasmaSensOut, CNC plasma cutting software, and CNC Plasma Z-axis & Floating head mechanics will play a pivotal role in shaping next-generation fabrication.

For businesses and operators, understanding these components is more than technical knowledge—it’s a competitive advantage. Whether you’re investing in new equipment, optimizing workflows, or training personnel, leveraging these innovations ensures superior results in an ever-evolving industry.

From intricate metal art to heavy industrial fabrication, the marriage of PlasmaSensOut, CNC plasma cutting, and the CNC Plasma Z-axis & Floating head proves that precision and efficiency are no longer mutually exclusive. As technology progresses, one thing remains certain: the cutting edge of manufacturing will always be defined by those who harness its full potential.